CERAMIC CASTING vs INVESTMENT CASTING

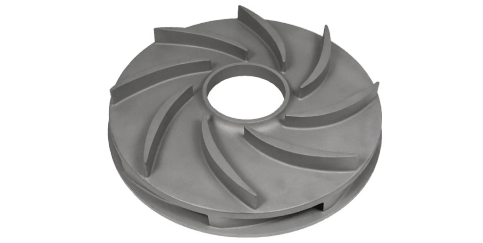

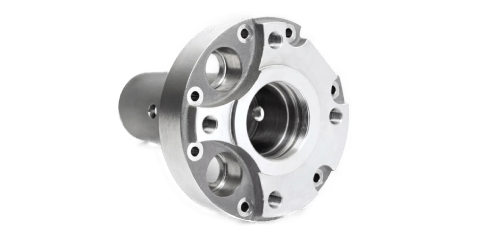

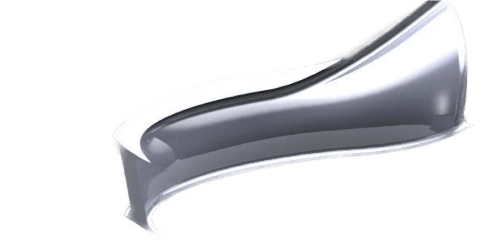

When it comes to casting processes, two methods often come into play: ceramic casting and investment casting. While both techniques involve the creation of intricate parts through molten material, they differ in various aspects that impact their applicability and outcomes.